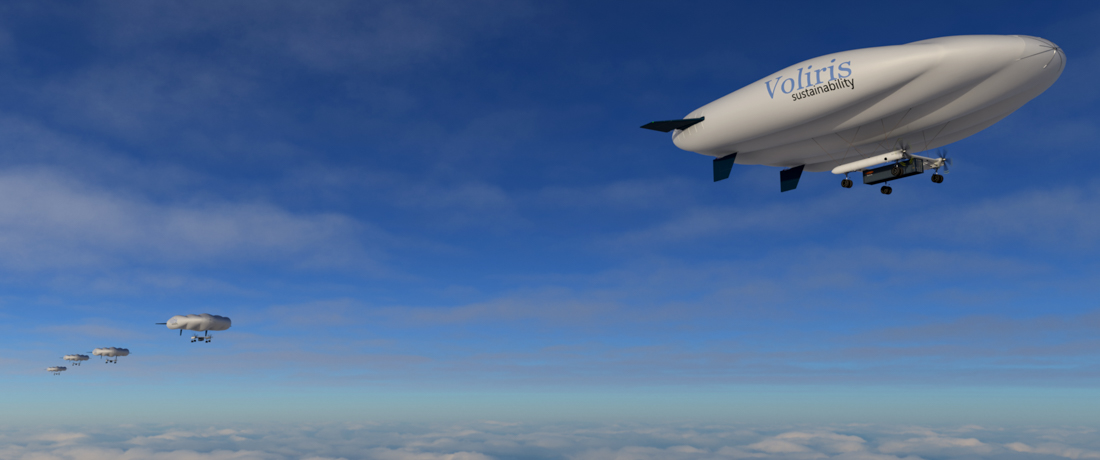

Through its subsidiary Michelin Inflatable Solutions, specialized in ultralight inflatable structures, Michelin is collaborating with Voliris in the development of NATAC, an automated air shuttle for container transport. In this way, the French company is leveraging its expertise in composites and their assembly to serve new generation technological products, specifically in this case, through the development of innovative industrial methods for the assembly of technical textiles, and sharing its knowledge of materials to support the manufacturing of the aircraft’s wing cover, which aims to transport goods without CO2 emissions, thanks to a flying wing adapted to areas with limited infrastructure – being heavier than air, this aircraft, still in the design phase, will not require ballast when depositing its load, thus having the potential to transform the air freight sector.

The wing cover is one of the most innovative elements of NATAC, due to the significant technical limitations it faces. Segmented into five lobes, it has a total volume of 25,000 m³, and arrives folded at the place of use, before being inflated. Its geometry is maintained through a pulley system, which varies its volume, adjusting its aerodynamic shape to different altitudes. In addition to this internal tension, the cover must withstand strong external stresses from the cables on which the load to be transported (up to 30 tons) is suspended, the mechanical tensions created by the inflation pressure over a large surface area (8,000 m²), and the need to remain airtight to helium and, ultimately, to hydrogen.

The manufacturing of a first full-scale demonstrator of the NATAC wing is expected to occur by 2028, for ground testing and validation of the in situ implementation of the shuttle – this will be the second key element of the project, following the successful flight tests conducted by a 1/7 scale prototype. To be able to operate in any area, the NATAC has a particularity: it can be transported in 10 standard 40-foot containers and is assembled directly at the take-off site. Therefore, the cover must be foldable without compromising its integrity, which represents an additional challenge.

In practice, this aerial shuttle is a hybrid solution, combining the characteristics of airships and cargo planes. It does not require a paved runway for take-off; to transport cargo with zero CO2 emissions, it has been designed to be 100% compatible with hydrogen, which, in the long term, will be used as fuel and lifting gas; and its autonomous flight system enables safe operations without personnel on board, allowing it to reach hard-to-access areas or those lacking heavy infrastructure.