Ferrari has inaugurated the new production unit in Maranello, where it will produce the brand’s first 100% electric model, alongside other hybrid and combustion models.

The “E-Building” has been under construction for two years and will house the internal assembly of high-voltage batteries, electric motors, and axles, supporting the production of Ferrari’s future models.

The new facility, with a total area of 42,500 square meters spread over four floors, led the Maranello brand to invest €200 million, with the aim of increasing manufacturing flexibility and reducing the time needed to develop and launch new models, rather than increasing production.

“This building will allow us to reduce the time it takes to bring products to market or develop them,” said Benedetto Vigna, CEO of Ferrari, at the inauguration of the new production unit.

To facilitate expansion, Ferrari acquired 39 buildings in Maranello and recovered “industrial land”, improving road networks and creating 1400 new parking spaces.

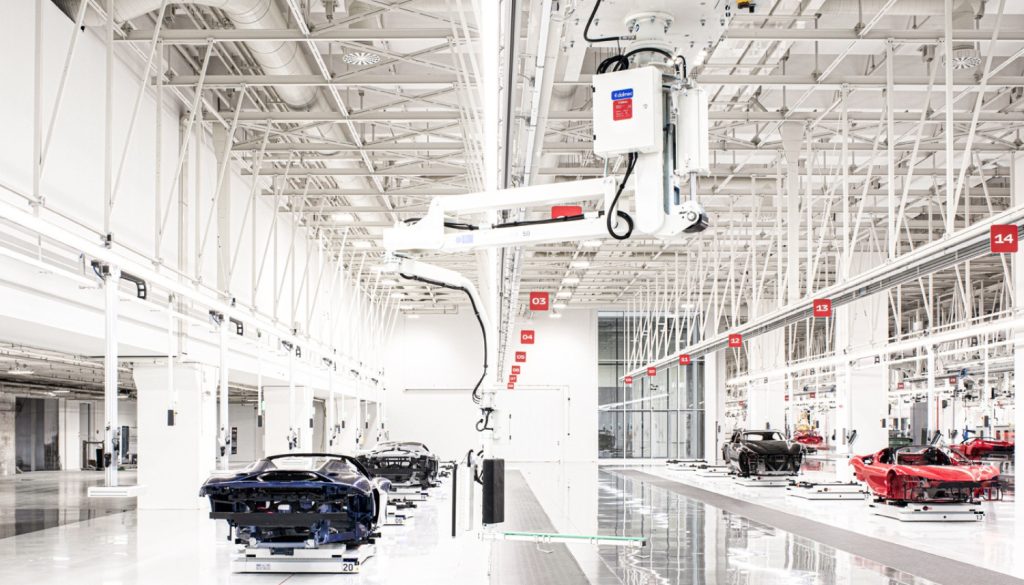

In addition to the numbers, the new facility corresponds to the definition of Factory 4.0: automated, digitized, and efficient, as the new installations store and recycle rainwater, have intelligent insulation and thermal properties throughout the year, and an air conditioning system powered by renewable energy. Furthermore, it is equipped with 3000 photovoltaic panels on the roof that produce a maximum power of 1.3 megawatts, contributing to a “nearly zero-energy building performance”.

In addition to skilled employees, Ferrari’s new factory will also use “anthropomorphic robots” in the new production line. Additionally, the workstations are “reconfigurable and highly ergonomic”. Employees will also have access to recreational areas and a training center.

The new production unit will allow Ferrari to produce new models with gasoline, hybrid, and fully electric engines, which according to the brand will contribute to increasing production by up to a third, from 13,663 units in 2023 to about 20,000 units per year, which could alleviate the long waiting lists and meet the growing demand, especially from emerging markets.

The company has not revealed details about the official start of production, nor about the specific models that will be manufactured at the new factory, which is expected to be operational within three to four months.