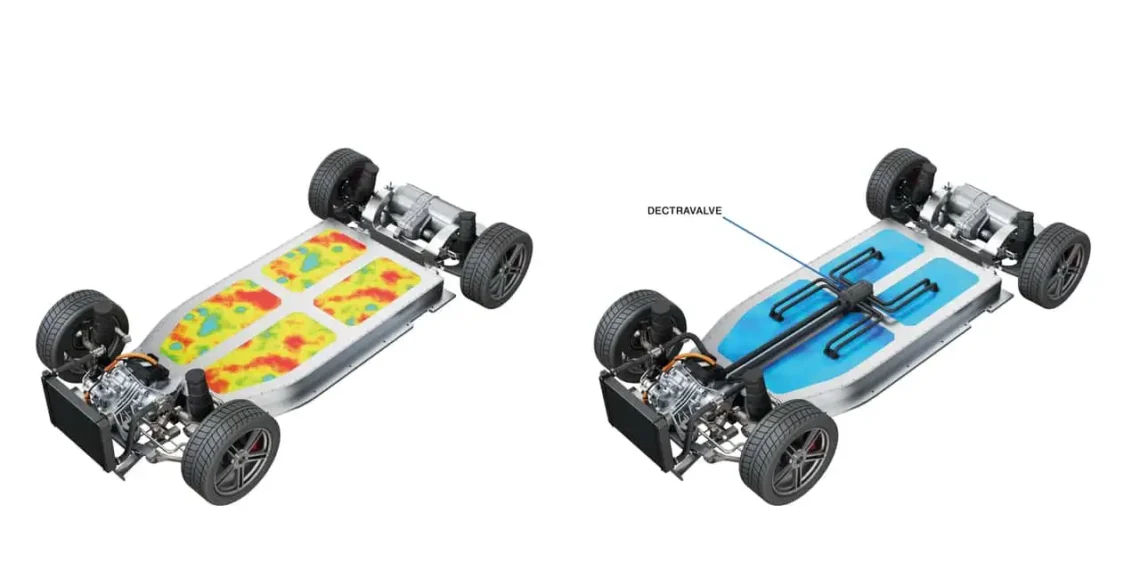

It is called Dectravalve, and it is a new technology, developed and patented by the British start-up HydroHertz, which could revolutionize the management of an electric car’s battery, particularly its thermal control. Thanks to more precise battery control, through the installation of a sophisticated valve system, this solution promises to offer several advantages, namely, reduced charging times, greater ranges, and an increase in battery life and safety in its use. The system includes a set of valves that allows the creation of distinct zones within the battery core, thus enabling more localized thermal control, which, according to HydroHertz, ensures more efficient heating and cooling, while also promoting a better energy recovery process, essential for the car’s efficiency.

In a fast charging test conducted by independent experts, a 100 kWh LFP chemistry battery, equipped with Dectravalve technology, subjected to a 350 kW charge, reportedly kept its hottest cell below 44.5º C, as well as maintaining a very stable temperature throughout the pack, with a variation of only 2.6º C between the hottest and coldest points. Charging 10.80% of the charge level under these conditions took about ten minutes.

In comparison with other load tests conducted with equivalent batteries, but without the new HydroHertz technology, the thermal variations are considerably higher, as there are records of temperature peaks of 56º C in some cells, as well as thermal amplitudes that can reach 12º C. According to the entity responsible for the load tests, when the temperature exceeds 50 ºC, the charging power must be reduced to avoid overheating of the cells, which can even cause damage to them. This also means that fast charging must be interrupted, significantly increasing the time required for it to be completed · and, in the test conducted with the new valve technology, this was not observed, even though the high power could have justified it.

Maintaining the temperature within ideal values means that the efficiency of battery usage is also optimized, resulting in considerably higher autonomy, which can lead to an improvement of up to 10%. And, since the operating temperature is significantly lower, the risk of overheating, and situations where safety could be compromised, is also reduced.

“A Dectravalve solves a fundamental problem of thermal management systems for electric vehicle batteries: how to achieve truly independent temperature control by zone, without the complexity, weight, and energy waste of multiple valve matrices”, says Martyn Talbot. The company also highlights another major argument for its Dectravalve technology: it can be applied to batteries of any chemistry, as well as to future configurations that are currently in development, which means its applicability is extensive. “Our innovation is elegantly simple: a single digitally controlled unit that can manage four or more cooling zones separately. With the Dectravalve, each cooling zone is completely independent, so the coolant flows from the pump to the battery and back again, in a specific circuit. There are no unwanted leaks of hot coolant between different zones, which would impair efficiency,” said the technical director of Hydrohertz.