After the successful use of renewable raw materials in competition models, the BMW Group has now announced that it will begin using natural fiber composites in series production models.

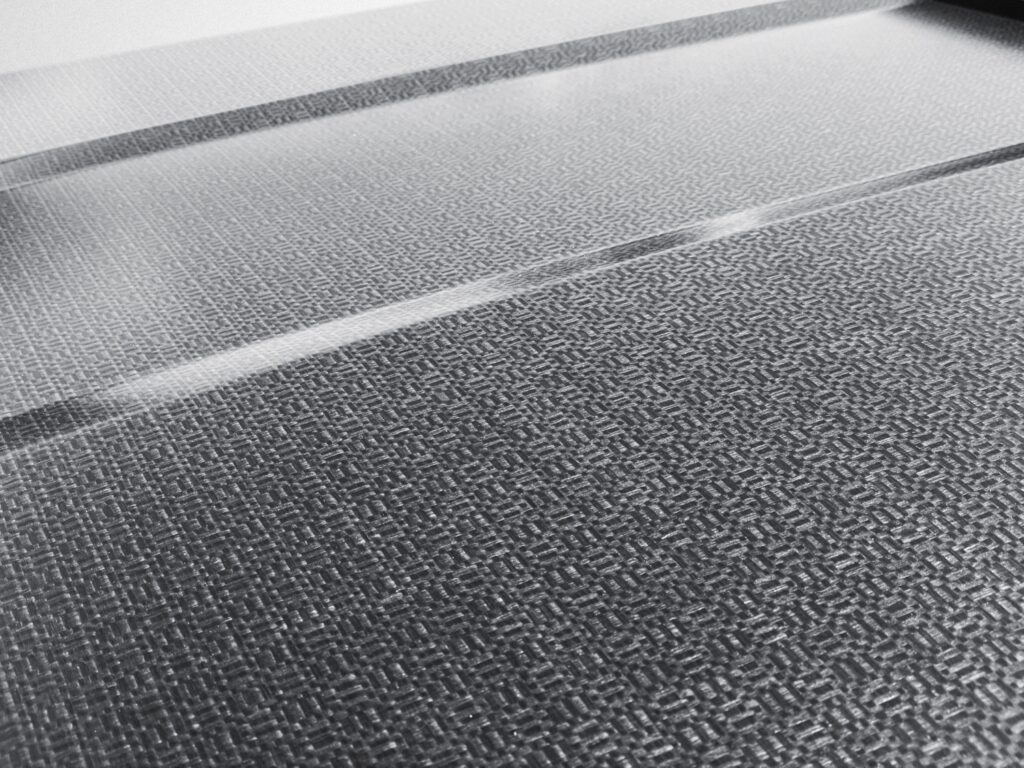

After several years of studies and tests, natural fiber composites meet even the rigorous requirements for roof structures in full vehicle homologation. The lightweight components based on linen have been developed in collaboration with Bcomp, a Swiss clean technology company, for several years.

The partnership with Bcomp supports the BMW Group’s goal of further reducing CO2 emissions in future vehicle models.

The innovative reinforcement parts made of natural fiber composites were initially used by BMW M Motorsport in the 2019 Formula E season. Since then, the components have also been successfully used in the BMW M4 DTM and M4 GT4, replacing carbon fiber plastic parts. These new materials will now undergo another durability test being installed in the BMW M4 GT4 that will line up in the next edition of the 24 Hours at Nürburgring.

“Natural fiber is an innovation that perfectly exemplifies the motto of BMW M: ‘Born on the track. Made for the streets.’ That is why we are pleased to confirm the maturity of these materials for series production. Now, we look forward to using these materials in future product lines from BMW M.”, said Franciscus van Meel, CEO of BMW M.