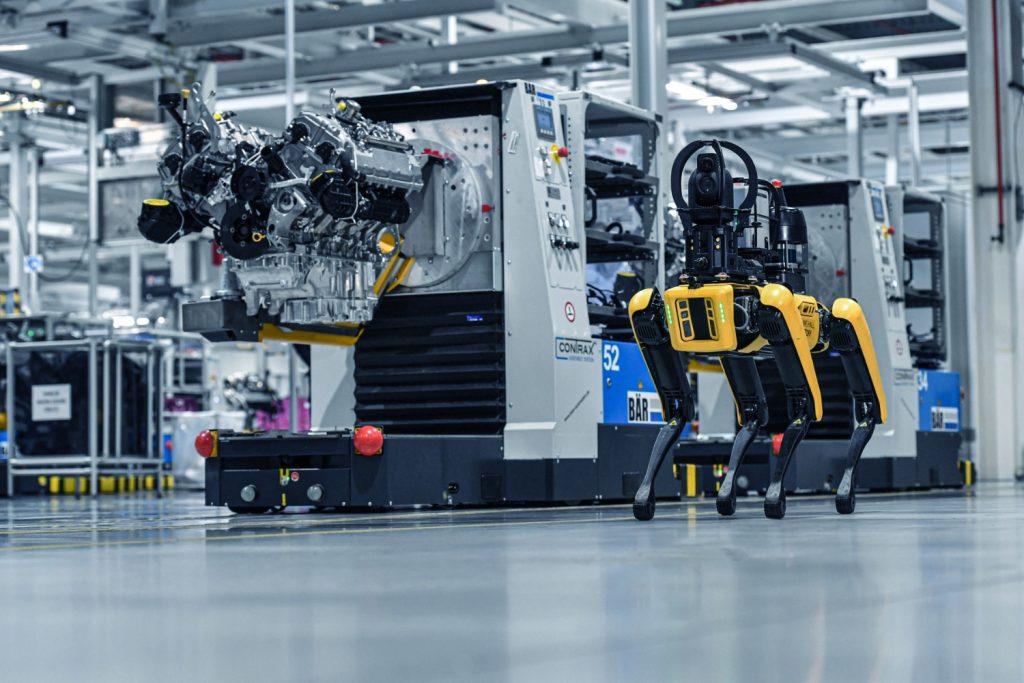

BMW is using a robotic dog to detect problems at the brand’s factory in the UK. This is SpOTTO, a product from Boston Dynamics, a company acquired by Hyundai in 2020, and one of the leading experts in robots with humanoid or four-legged forms.

The BMW production unit in the UK produces 400,000 BMW turbo engines and Mini TwinPower engines per year, and SpOTTO’s function is to keep the machines in good condition and anticipate any kind of problem.

To do this, the robotic dog uses visual, thermal, and acoustic sensors to detect problems at the equipment’s temperature level, anticipating a possible failure. In addition, it is able to detect breaks in the compressed air lines used in the production line.

SpOTTO was created by Boston Dynamics with the product name “Spot.” It is an agile robot, small enough to be used in indoor environments, that can climb stairs and traverse rough terrain with ease.

BMW revealed that the new robot dog was named SpOTTO in honor of Gustav Otto, one of BMW’s founders, as well as his son Nicolaus, the inventor of the four-stroke internal combustion engine.

Seen as a technology that allows for anticipating issues in the production line, SpOTTO also has the mission of collecting data that contributes to ensuring quality and production planning.