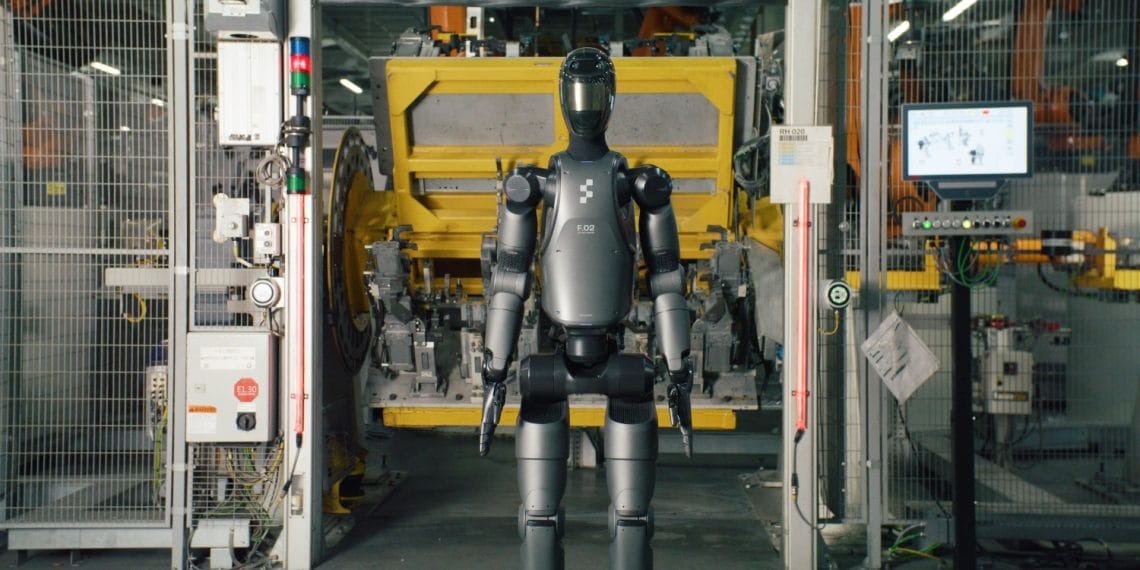

BMW announced that it successfully tested the humanoid robot F.02 from the American company Figure in a real production environment at the Spartanburg factory in South Carolina, USA.

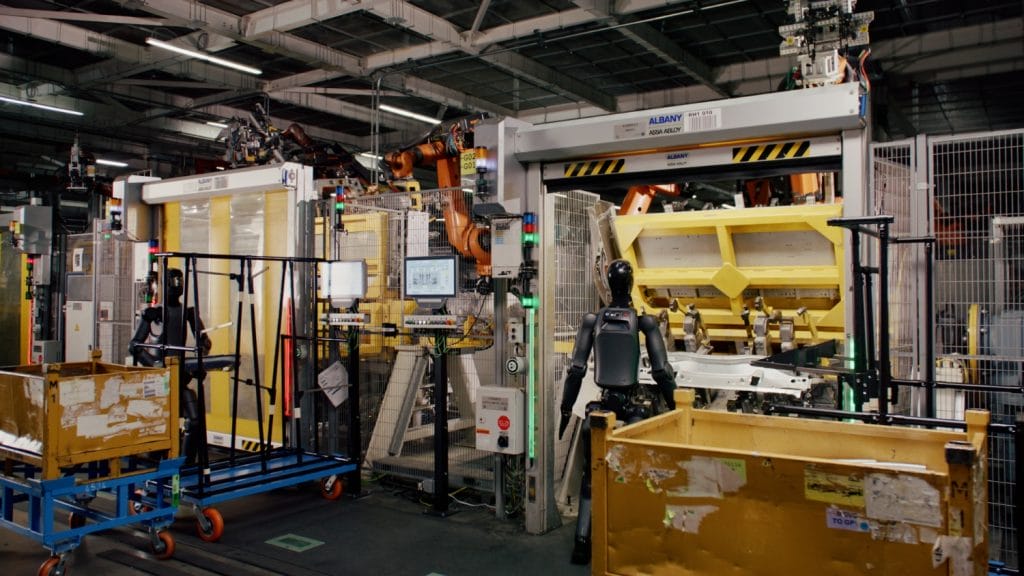

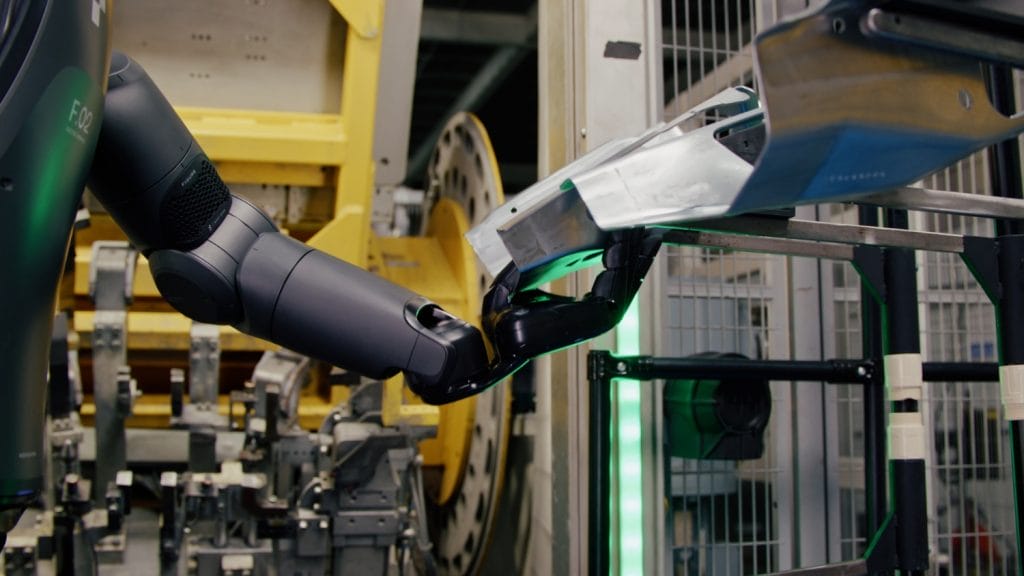

The robot was used for the insertion of sheet metal parts into specific fixations that were later used to assemble part of a vehicle chassis.

According to Figure, the 02 is the most advanced humanoid robot currently available on the market. The combination of two-legged mobility and advanced dexterity means that Figure 02 is ideal for use in areas with physically demanding, unsafe, or repetitive processes, thus improving ergonomics and safety.

The American company has revealed that the robot boasts three times the processing power of its predecessor, improved voice communication, better cameras, microphones, and sensors, a high-performance 2.25 kWh battery capable of providing up to 20 hours of autonomy, and hands that produce human-equivalent force with 16 degrees of freedom.

“Developments in the field of robotics are very promising. After the initial test, we are now determining the possible applications for humanoid robots in production,” said Milan Nedeljković, member of the Board of Management for Production at BMW AG.

The German brand revealed that there is currently no definitive timeline for when humanoid robots like Figure 02 will be permanently used in their production unit in the USA.