Mercedes-Benz is accelerating the transformation of its production network by strengthening the role of Berlin-Marienfelde as an innovation center for MO360 digital production technologies, now enhanced with Artificial Intelligence (AI), humanoid robots, and pioneering innovations such as the production of high-performance axial flow electric motors.

Established in 2022, Berlin-Marienfelde has positioned itself as the global competence center for production digitalization with the Mercedes-Benz Digital Factory Campus (MBDFC), promoting the development of future software applications in a real production environment.

The central foundation of the activities is the Mercedes-Benz Cars Operations 360 digital production ecosystem, or MO360, which encompasses all the important software applications and data from the global production network. At the MBDFC, the development and testing of new processes and technologies have been combined with the rapid and seamless global implementation of pioneering MO360 software applications for automotive production.

Mercedes-Benz has now refined its MO360 production system with AI capabilities, such as the Digital Factory Chatbot Ecosystem and the MO360LLM Suite, along with humanoid robots from the American company Apptronik, reinforcing Berlin-Marienfelde’s status as a global innovation center.

New production processes and resources, including those enabled through the Mercedes-Benz Operating System (MB.OS), are being tested before being sent to real production lines in other Mercedes-Benz assembly plants.

Marienfelde, for example, has played an important role in preparing the Rastatt plant for the increased production of the new Mercedes-Benz CLA, the first vehicle to incorporate MB.OS, which was presented just a few days ago.

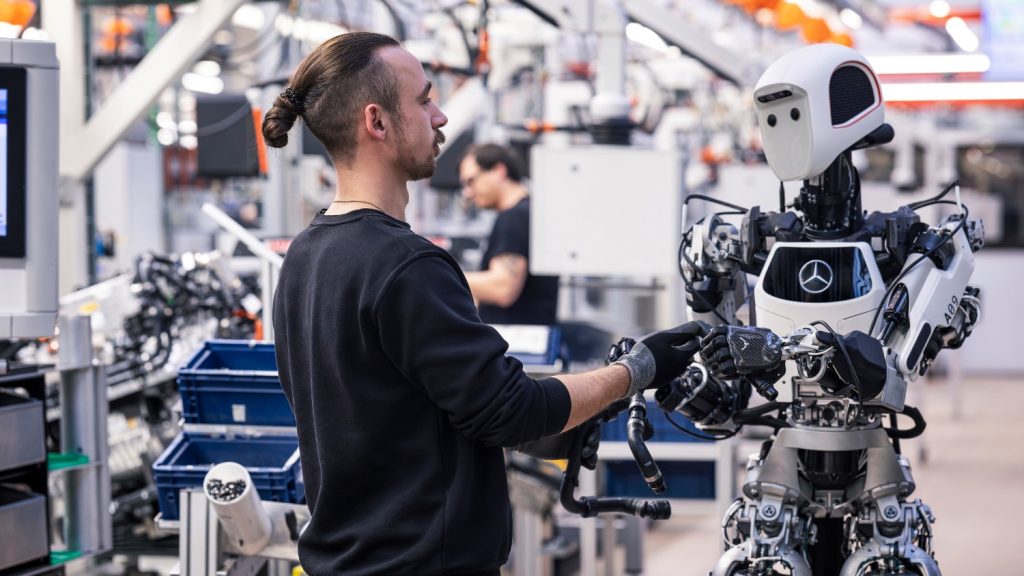

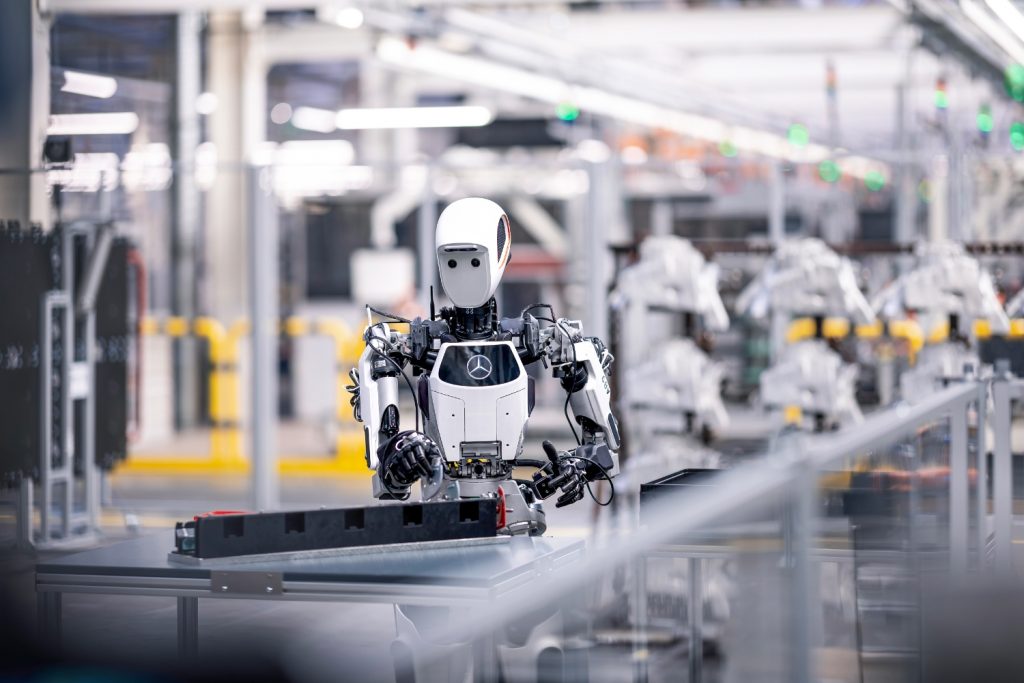

Committed to empowering its employees with cutting-edge technology – and with Apollo, Mercedes-Benz is bringing one of the world’s most advanced commercial humanoid robots to its manufacturing facilities. To underscore its commitment to deploying humanoid robots in automotive production, the German brand will make a low double-digit million euro investment in Apptronik, founded in 2016 at the Human Centered Robotics Lab at the University of Texas at Austin.

Currently, Mercedes-Benz is testing the integration of humanoid robots in production, with an initial focus on repetitive tasks within intra-logistics. The Apollo from Apptronik can be used to transport components or modules to the production line, where highly skilled Mercedes-Benz employees assemble them, and to perform initial quality checks on the components.

The Apollo robots have been collecting data in a production environment to train for specific use cases within MO360. Mercedes-Benz employees with real production knowledge have transferred their expertise to the Apollo using teleoperation and augmented reality processes.

Mercedes-Benz is now taking the next decisive step in development at the Digital Factory Campus in Berlin – enabling the Apollo robots to perform autonomous operations, a technological milestone on the path to a flexible and intelligent assistance system for production.